3D Laser Lithography

Contact Person: Bogdan C?LIN

E-mail: bogdan.calin@inflpr.ro

Phone: 2423

E-mail: bogdan.calin@inflpr.ro

Phone: 2423

|

System Components

|

Performances

|

Features

|

|

Technology

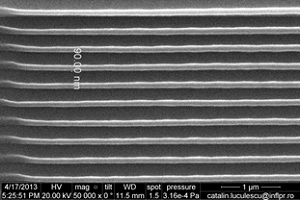

3D Laser Lithography is a Laser Direct-Writing (LDW) technique based on Two-Photon Polymerization (TPP) effect in photoresists.

Starting from a 3D CAD file (STL), by rapid prototyping algorithms fully three dimensional structures can be fabricated with submicrometer resolution.

A General Writing Language (GWL) script allows complex 3D designs and full control over the scanning path, laser exposure, automatic positioning and corrections.

Applications:

- Micro-optics

- Photonic crystals and metamaterials

- Scaffolds for tissue engineering

- Micro-fluidics

- 2D masks

References:

[1] Florin Jipa, Marian Zamfirescu, Alin Velea, Mihai Popescu and Razvan Dabu (2013). "Femtosecond Laser Lithography in Organic and Non-Organic Materials", Chapter in:"Updates in Advanced Lithography", Prof. Sumio Hosaka (Ed.), ISBN: 978-953-51-1175-7, InTech, DOI: 10.5772/56579. Available online at Intech.

[1] Florin Jipa, Marian Zamfirescu, Alin Velea, Mihai Popescu and Razvan Dabu (2013). "Femtosecond Laser Lithography in Organic and Non-Organic Materials", Chapter in:"Updates in Advanced Lithography", Prof. Sumio Hosaka (Ed.), ISBN: 978-953-51-1175-7, InTech, DOI: 10.5772/56579. Available online at Intech.